-

Multi Packing Machine

-

Screw Air Compressor

-

VFFS Packing Machine

-

Vacuum Seal Packing Machine

-

Corrugated Box Packing Machine

-

Tea Bag Packing Machine

-

Automatic Cartoning Machine

-

Aseptic Carton Filling Machine

-

Robot Palletizer Machine

-

Cup Filling Sealing Machine

-

Direct Drive Air Compressor

-

Reciprocating Piston Compressor

-

Oil Free Screw Air Compressor

-

Oil Free Piston Air Compressor

-

Air Compressor Head

-

Gasoline Portable Generator

-

Air Compressor Spare Parts

-

Fill Seal Packaging Machine

-

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

Photoelectric Sachet Cartoning Machine Automatic Box Filling 1700mm

| Place of Origin | China |

|---|---|

| Brand Name | CHIC |

| Certification | CE ISO |

| Minimum Order Quantity | 1 piece |

| Packaging Details | Packing inside is plastic films and outside is fumigation wooden case.Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine cor |

| Delivery Time | 30 working days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20 pcs /month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Full Automatic Tea Bag Box Facial Wet Tissue Boxing Sachet Cartoning Packaging Machine | Driven Type | Electric |

|---|---|---|---|

| Voltage | 380v 50hz 3 Phase | Capacity | 50-60 Cartons/min |

| Dimension | 2800*1350*1700 Mm | Carton Size | L: 70-200mm; W: 40-160mm; H: 15-70mm |

| Highlight | Photoelectric sachet cartoning machine,1700mm sachet cartoning machine,1700mm automatic box filling machine |

||

Full Automatic Tea Bag Box Facial Wet Tissue Boxing Sachet Cartoning Packaging Machine

Application:

Automatic Box Cartoning Machine is a hot sale product developed and manufactured by our company. It is applied to a variety of foods, toys, cosmetics, electronics and daily necessities. The working process is as follows: automatic box forming, feeding, folding, glue spraying and sealing. It saves a lot labour cost which equal of 8-20 workers.

Specifications :

|

Model No.

|

CHIC-ZHPJ-V3

|

|

Product Name

|

Automatic Box Cartoning Machine

|

|

Air Consumption

|

200-400L/min.

|

|

Power

|

5 kw

|

|

Voltage

|

380/220V 50Hz

|

|

Machine Weight

|

1000 – 1500 kgs

|

|

Overall Dimension

|

(L)2800mm x (W)1500mm x (H)1650mm

|

|

Box Packing Speed

|

40-60 boxes/min.

|

|

Box Material

|

250-350g/m2 or corrugated cardboard

|

|

Box Size

|

L: 70-200mm; W: 40-160mm; H: 15-70mm

|

|

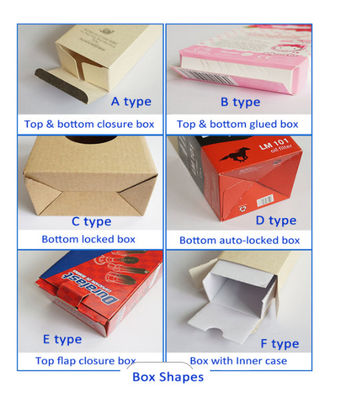

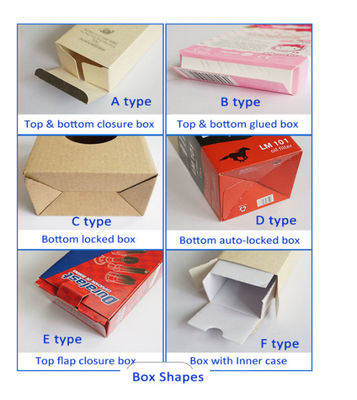

Can be customized according to your box shape and size

|

Feature:

1, Adopt PLC automatic control system, frequency conversion. The electrical components adopt international famous brands.

2, Photoelectric system monitors all parts moving. If there is malfunction during the running, the wrong place will be shown and the machine can stop automatically.

3, Reject automatically the box which is lack of stuff or specification.

4, If the stuff or specification lack, the paper box will stop feeding.

5, Performance is stable. The operation is easy and convenience.

6, The machine can feed and box continually, the machine can instead of 15-20 the workload of workers.

machine accessory list:

| No. | Name | Brand | Made in |

| 1 | The main body | Stainless steel | China |

| 2 | electric elements | Schneider / OMRON | french/japan |

| 3 | pneumatic | AIRTAC | Joint venture |

| 4 | Bearing | Luoyang | China |

| 5 | servo motor | Panasonic | JAPAN |

| 6 | PLC | Siemens | German |

| 7 | Touch screen | Siemens | German |

| 8 | Driver | Starlight transmission | China |

Pre-Sale Service:

We will according your product feature, weight of each bag, and shape of bag make a quotation for your. Then more details we need communication sunch as material and thickness of film, dimension of bag you already have it or need we design for you, Operate language,what kind of voltage at the local.

After-Sale Service:

Warranty: 1 Year excep wearing parts ( Cutter, Belt, Horizontal and vertical Heating Tube etc)Most of components are free-replacement (PLC,Servo controller,Servo motor,Touch screen,cylinder) . Machine delivery will with a tool box, there have some parts is free.

Operation training: 1:Machine is very easy operate, delivery with manual, offer lot of photo and video when machine in assembling or disassembling. 2: Welcome to our factory learning. 3: Engineers available to service machinery overseas.

Kindly reminder:

Please let us know the follow packing details when you offer,so that we can check if this model is suitable for your case.Thank you in advance.

1. Product details

2. Bag width,bag length

3. Bag shape

4. Packing film material

5. Machine frame