-

Multi Packing Machine

-

Screw Air Compressor

-

VFFS Packing Machine

-

Vacuum Seal Packing Machine

-

Corrugated Box Packing Machine

-

Tea Bag Packing Machine

-

Automatic Cartoning Machine

-

Aseptic Carton Filling Machine

-

Robot Palletizer Machine

-

Cup Filling Sealing Machine

-

Direct Drive Air Compressor

-

Reciprocating Piston Compressor

-

Oil Free Screw Air Compressor

-

Oil Free Piston Air Compressor

-

Air Compressor Head

-

Gasoline Portable Generator

-

Air Compressor Spare Parts

-

Fill Seal Packaging Machine

-

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

Plastic Pouch Small Bag Pure Water Liquid Sachet VFFS Packaging Machine

| Place of Origin | China |

|---|---|

| Brand Name | chic |

| Certification | ISO CE |

| Minimum Order Quantity | 1 SET |

| Packaging Details | Packing inside is plastic films and outside is fumigation wooden case.Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine cor |

| Delivery Time | 20 working days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 200sets per year |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Liquid VFFS Packing Machine | Type | New Vertical Packaging Machine |

|---|---|---|---|

| Packing Material | Bags, Film, Foil, Pouch | Application | Food, Beverage, MEDICAL, Chemical |

| Demision | L 880*W 760*H 1800mm | Packing Speed | 30-70bags/min |

| Material | 304SS | Bag Shape | Pillow Bag/Stick Sachet/3 Side Sealing/4 Side Sealing/Custom Made |

| Highlight | Sachet VFFS Packaging Machine,Plastic Pouch VFFS Packaging Machine |

||

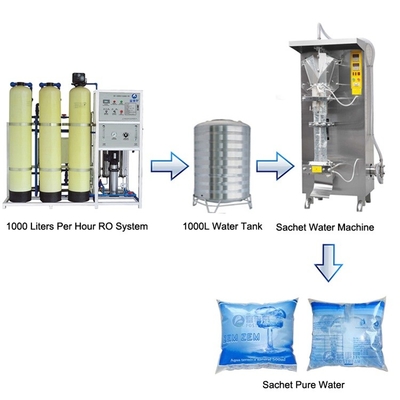

Automatic Plastic Pouch Liquid Sachet Water Filling Machine

Appications:

Automatic Plastic Pouch Liquid Sachet Water Filling Machine It is applicable for packing the liquid like pure water, mineral water, fruit juice, milk, soy milk and coconut milk etc.

Specification:

We have several Models.

Don't Worry! We can customize the suitable one for you according to your requiredment.

Just Tell us : Weight or Bag Size required.

| Model | FS-1000 | FS-2000 |

| Bag Making Length | 50-150mm | 50-250mm |

| Bag Making Width | 40-150mm | 40-175mm |

| Packing Use Film Width | 100-320mm | 100-380mm |

| Packing Volume | 50-550ml | 200-1000ml |

| Packing Speed | 1800-2200Sachets/Hr | 1000-1300Sachets/Hr |

| Total Power | 1.6KW | 2.5KW |

| Dimension | 880*760*1800mm | 1050*850*2050mm |

| Weight | 275KGS | 380KGS |

| Film distribution type | Gear Moving Mechanical Control | |

| Monitoring Sensor | NO | |

| Option Solutions | Ribbon Date Coding Is Available: $40 Additional | |

| Anti-Dust Cover is Available: $30 Additional | ||

| Model | FS-1000LX | FS-2000ZFLX |

| Bag Making Length | 50-150mm | 50-250mm |

| Bag Making Width | 40-150mm | 40-175mm |

| Packing Use Film Width | 100-320mm | 100-380mm |

| Packing Volume | 50-550ml | 200-1000ml |

| Packing Speed | 1800-2200Sachets/Hr | 1000-1300Sachets/Hr |

| Total Power | 2.1KW | 2.5KW |

| Dimension | 1050*850*1800mm | 1050*850*2050mm |

| Weight | 375KGS | 380KGS |

| Film distribution type | Motor Control depending on different sachet size, Film sending length is precise | |

| Monitoring Sensor | Photocell Sensor : Can cut & seal 100% elegant according to Film Logo &AD Pre-printed | |

| Option Solutions | Touch Screen Function :$480 Additional | |

| Ribbon Date Coding Is Available: $40 Additional | ||

| Anti-Dust Cover is Available: $30 Additional | ||

![]()

![]()

1) Basic features of the sachet filling packing machine:

Auto Film Feeding+ Vertical Forming Sealing + Horizontal Sealing + Quantitive Filling + Uv System + Date Coding / Counting

2) Structure of the machinery:Basic Type: SJY-1000 Series Technical Specification

01. Frame and Liquid Contacting parts are S.S304. Equipped with water pump for the water filling purpose and motor and speed reducer control unit for the speed control of the film distribution system.

02. Film dispensing unit: is composed of film setting system, film guiding SS304 steel post, vertical thermal heating sealing rubber and the copper system, horizontal thermal sealing and cutting system. The film will be

forming according to the film setting process, to make the bags ready for filling water.

03. Filling unit: is composed of water pump, inlet control valve, Quantities will be depending on the piston type filler.

04. Auto sealing system: is composed of the film inlet guiding post, wheel, and the thermal heating modular, thermal heating tube, temperature controller, and pressure adjusting spring valve.

05. Film output system: is composed of SS304 sliding rail plate.

06. Electrical control system: is composed of control panel, wiring, and the AC contactor system.

07. UV sterilizer and date coder is equipped on the machine

08. Data counting unit is equipped on the front panel.

09. Photo sensor for the speed control and the logo position correcting system will be equipped on the SJY-ZF1000 Series

Installation:

1- We provide videos and instruction manual to show the process of installation.

2- We provide training for installation for free in our factory.

3- We can send technician to buyer's factory to install the machine and provide training service,but customer affords the engineer’s visa fee, double-flight fee, hotel fee and 100USD per day salary.

After Sales Service:

1- One year quality warranty and free lifetime technique support.

2- Free spare parts would be supplied if machine broken within warranty period.

3- After the warranty period, the spare parts for replacement are offered based on certain charge.

Machine details:

FAQ

Q1: How to find a Packing machine suitable for my product?

Tell us about your product details and packing requirements.

1. What kind of product you would like to pack?

2. The bag/sachet/pouch size of you need for the product packing(the length and width).

3. The weigh of each pack you need.

4. You requirement for the machines and the bag style.

Q2: Is engineer available to serve oversea?

Yes, but the travel fee is responsible by you.

In order to save your cost, we will send you a video of full details machine installation and assist you till the end.

Q3. How can we make sure about the machine quality after placing the order?

Before delivery, we will send you the pictures and videos for you to check the machine quality.

And also you can arrange for quality checking by yourself or by your contacts in China.

Q4. We are afraid you won't send us the machine after we send you the money?

We have our business license and certificate. And it is available for us to use Trade assurance service, guarantee your money and guarantee your machine's on-time delivery and machine quality.

Q5. Can you explain me the whole transaction process ?

1. Sign the Contact

2. Arrange 30% deposit to our factory

3. Factory arrange production

4. Testing & detecting the machine before shipping

5. Inspected by customer or third agency through online or site test.

6. Arrange the balance payment before shipment.

Q6: Will you provides the delivery service?

A: Yes. Please inform us of your final destination, we will check with our shipping agent to quote the shipping cost for your reference before delivery.FAQ