-

Multi Packing Machine

-

Screw Air Compressor

-

VFFS Packing Machine

-

Vacuum Seal Packing Machine

-

Corrugated Box Packing Machine

-

Tea Bag Packing Machine

-

Automatic Cartoning Machine

-

Aseptic Carton Filling Machine

-

Robot Palletizer Machine

-

Cup Filling Sealing Machine

-

Direct Drive Air Compressor

-

Reciprocating Piston Compressor

-

Oil Free Screw Air Compressor

-

Oil Free Piston Air Compressor

-

Air Compressor Head

-

Gasoline Portable Generator

-

Air Compressor Spare Parts

-

Fill Seal Packaging Machine

-

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

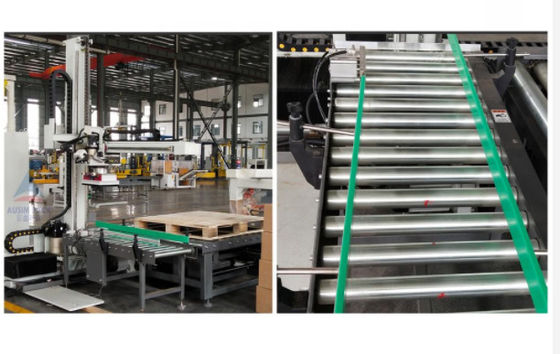

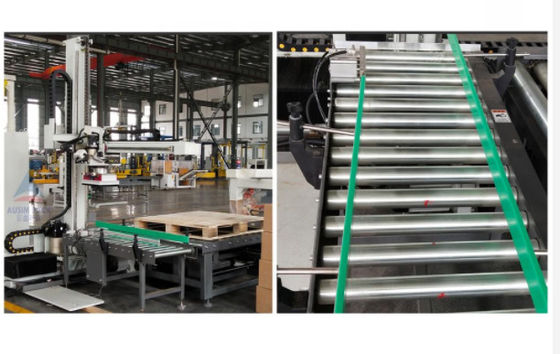

Servo Box Robot Palletizer Machine For Bottles Bags Cartons 600kg

| Place of Origin | China |

|---|---|

| Brand Name | CHIC |

| Certification | CE ISO |

| Minimum Order Quantity | 1 piece |

| Packaging Details | Packing inside is plastic films and outside is fumigation wooden case.Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine cor |

| Delivery Time | 25 working days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20 pcs/month |

Contact me for free samples and coupons.

Whatsapp:0086 18588475571

Wechat: 0086 18588475571

Skype: sales10@aixton.com

If you have any concern, we provide 24-hour online help.

x| Name | Small Economic Cost Save Type Automatic Robotic Box Palletizer,servo Palletising Machine With 30kgs Loading Weight | Packing Type | For Bottles, Bags, Cartons |

|---|---|---|---|

| Dimension | L 2200*W 2000*H 2600mm | Weight | 600kg |

| Driver | Mitsubishi Servo Motor | Air Cylinder | AirTAC/FESTO |

| Speed | 20-50 Pallets/hr | ||

| Highlight | Box Robot Palletizer Machine,Servo Robot Palletizer Machine,Servo box palletizer machine |

||

Servo Box Robot Palletizer Machine For Bottles Bags Cartons 600kg

Product Application

The palletizer is used to palletize the cartons that have been loaded into vessels onto pallets (wood, plastic) according to certain arrangements for automatic piling. The cartons can be piled into multiple layers and pushed out, and can be conveniently conveyed by the forklift truck to the warehouse for storage. The equipment adopts PLC + touch screen control, realizing intelligent operation and management. It is convenient and easy to operate. It can greatly reduce labor force and lower labor intensity. It is designed with the concepts of high speed, stability, and space saving. It adopts split type plate release, which is faster and saves more space. With multiple functions in one machine, it realizes adjustment rapidly and frees you from the worry of replacing the piled products. Application range: corrugated cases, plastic cases, barrel-shaped packaging materials, and bag-shaped packaging materials.

Features

Touch screen operation is adopted to accomplish the man-machine dialogue, using the Siemens PLC programmable control number

The symmetry and compact structure design, suitable for the narrow space of the existing production sites

Taken the pallet database is big, can accommodate 15 empty pallet, which can realize automatic supply pallet. (pallet library is optional)

Don't have to change the stacking parts can complete several stacking way, only need to obtain the parameters is ok.

Specifications:

|

Capacity

|

5-6Boxes/Min (It depends on box size and weight)

|

|

|

Pallet Size

|

1100*1100mm/1200*1200mm/1200*800mm/1000*1000mm

|

|

|

Power Supply

|

380V,3Phase,50-60Hz

|

|

|

Stacking Height

|

1800/2400mm

|

|

|

Machine Size

|

L2200*W2000*H2800mm

|

|

|

Air consumption

|

0.6-0.8Mpa

|

|

|

Conveyor H

|

650+-50mm

|

|

|

weight

|

600KGS

|

|

Machine details:

![]()

![]()

Installation and adjustment

After the equipments are arrived at the customer’s site, the customers is responsible for unpacking and arranging the equipment according to the placement drawing; and do under our install-adjust technicians’ guidance.

According to requirement of water, electricity, air and steam consumption and the demands of quality level and pipeline, the User should connect the wire, cable and pipe of water, air and steam to the special position ordered in the installation area of production line ahead of time. Other relevant matching equipment and project should be finished before we adjust our equipment.

We’ll bring a suit of portable installation and adjustment tools ourselves during the period of installing and adjusting, the other instruments we need should be furnished by the customer for free including oxygen, acetylene angry, argon, etc. needed in the installation and adjustment site.

The customer should dispatch the capable person to accept training in the installing site.

Quality assurance

We guarantee the goods offered are brand-new, unused, with latest design and suitable material made, and we guarantee the specification of the equipments is consonance with the contract.

We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc that all belong to our responsibility.

Maintenance

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason. We will offer a widely and favorable technical support, after service all the time after guarantee period.