-

Multi Packing Machine

-

Screw Air Compressor

-

VFFS Packing Machine

-

Vacuum Seal Packing Machine

-

Corrugated Box Packing Machine

-

Tea Bag Packing Machine

-

Automatic Cartoning Machine

-

Aseptic Carton Filling Machine

-

Robot Palletizer Machine

-

Cup Filling Sealing Machine

-

Direct Drive Air Compressor

-

Reciprocating Piston Compressor

-

Oil Free Screw Air Compressor

-

Oil Free Piston Air Compressor

-

Air Compressor Head

-

Gasoline Portable Generator

-

Air Compressor Spare Parts

-

Fill Seal Packaging Machine

-

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

Mr.Isaac AsareOlar and the technical team at Xianyang Chic Machinery Co., Ltd were quick to answer questions and walk the Installation team through it all. In the end, the machine is working fine, and we are happy with this purchase.

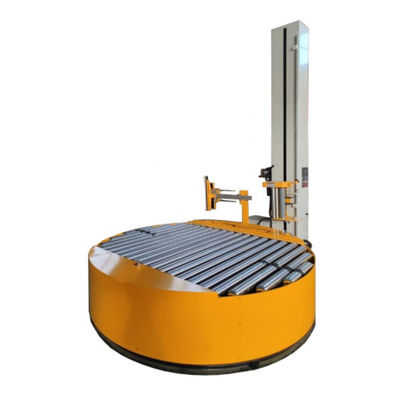

Full Automatic 400mm Pallet Wrapping Machine Paller Wrapper Stretch TP2000FZ

| Place of Origin | China |

|---|---|

| Brand Name | CHIC |

| Certification | CE ISO |

| Minimum Order Quantity | 1 piece |

| Packaging Details | Packing inside is plastic films and outside is fumigation wooden case.Our wooden case is very strong,it can bear long time shipping on the sea.And machine with preservative film,it can stop the salt sea water enter into the machine and make the machine cor |

| Delivery Time | 25 working days |

| Payment Terms | L/C, T/T, Western Union |

| Supply Ability | 20 pcs/month |

| Name | Full Automatic Paller Wrapper , Online Pallet Wrapping Machine Pallets Robot Palletizer Machine | Packing Type | Cartons, CANS, Bottles, Barrel, Bags, Case, Pallet |

|---|---|---|---|

| Dimension | L 3200 X W 2000 X H 2100mm | Table Height | 400mm |

| Speed | 30-50 Pallets/hr | Max. Loading | 2000kg |

| Wrapping Height | 500-1800/2400mm | Wrapping Size | L (500-1100)* W (500-1200)mm |

| Highlight | 400mm pallet wrapping machine,TP2000FZ pallet wrapping machine,TP2000FZ stretch wrapping machine |

||

Full Automatic 400mm Pallet Wrapping Machine Paller Wrapper Stretch TP2000FZ

Product Application

Features

• Open door film carriage

• Magnetic brake holds turntable still during loading/unloading

Specifications:

|

Model

|

TP2000FZ

|

|

Voltage

|

380V 50HZ 3P

|

|

Power

|

Turntable Motor: 0.75kw, Film Motor: 0.4kw, Column Motor: 0.37kw

|

|

Wrapping Size(L*W mm)

|

(500-1100)*(500-1200)

|

|

Wrapping Height

|

500-1800/2400

|

|

Capacity

|

20-40 Pallet/Hour

|

|

Turntable size

|

2000mm

|

|

Turntable Height

|

400mm

|

|

Max loading

|

2000kg

|

|

Speed

|

Adjustable

|

|

Machine Size

|

3200*2000*2100mm

|

Machine details:

![]()

Installation and adjustment

![]()

After the equipments are arrived at the customer’s site, the customers is responsible for unpacking and arranging the equipment according to the placement drawing; and do under our install-adjust technicians’ guidance.

According to requirement of water, electricity, air and steam consumption and the demands of quality level and pipeline, the User should connect the wire, cable and pipe of water, air and steam to the special position ordered in the installation area of production line ahead of time. Other relevant matching equipment and project should be finished before we adjust our equipment.

We’ll bring a suit of portable installation and adjustment tools ourselves during the period of installing and adjusting, the other instruments we need should be furnished by the customer for free including oxygen, acetylene angry, argon, etc. needed in the installation and adjustment site.

The customer should dispatch the capable person to accept training in the installing site.

Quality assurance

We guarantee the goods offered are brand-new, unused, with latest design and suitable material made, and we guarantee the specification of the equipments is consonance with the contract.

We are responsible for the fault and damage of the production line caused by our design, technology, manufacture, installation, adjustment and material defect etc that all belong to our responsibility.

Maintenance

Offer 12 months maintenance period to the problem that caused by our design, manufacture and the material quality, and offer the relevant parts and effective service for free for above reason. We will offer a widely and favorable technical support, after service all the time after guarantee period.